With roller bearings, CRB Antriebstechnik offers mechanical components that serve to reduce friction and wear by distributing the load on small contact surfaces. They enable moving parts in machines and systems to move smoothly against each other.

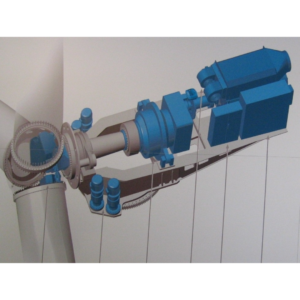

Roller bearings are available in different designs, such as ball or roller bearings, which differ depending on the application and load. They can withstand both radial and axial loads and can be found in many areas of technology, such as automotive, mechanical engineering, electrical engineering, and wind energy.

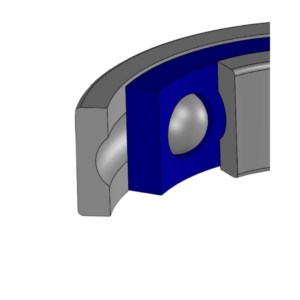

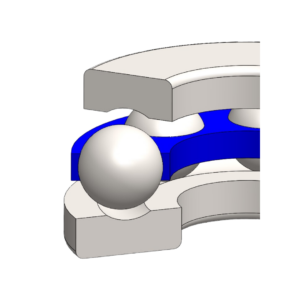

Deep groove ball bearings are a universally applicable type of bearing that are among the most commonly used types of bearings.

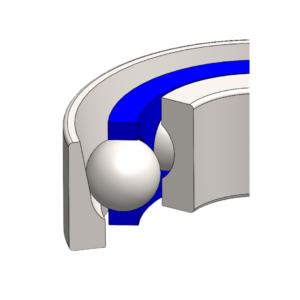

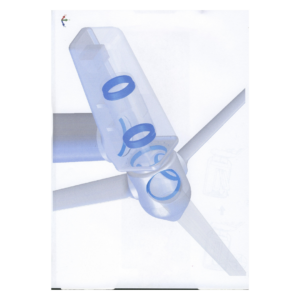

Deep groove ball bearings are a special type of roller bearing that are particularly suitable for high speeds and loads. They consist of an inner and an outer ring as well as balls that are mounted in grooves on the bearing rings. The grooves provide a higher load-bearing capacity because the balls are better retained on the bearing rings. Deep groove ball bearings are particularly suitable for applications where high speeds and loads are present, such as in electric motors, machine tools, or fans.

Another advantage of these bearings is their maintenance-free operation. Unlike other types of roller bearings, they do not need to be lubricated regularly, which saves time and money. They are also more resistant to environmental influences such as moisture and dirt.

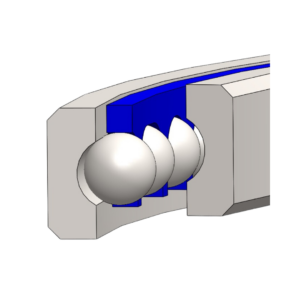

Cylindrical roller bearings consist of an inner and outer ring, cylindrical rollers, and are available with or without a cage. The cage serves to prevent contact between the individual rolling elements. These bearings are characterized by their high load-carrying capacity.

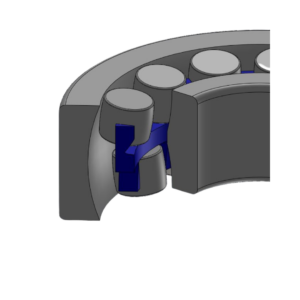

Spherical roller bearings have 2 rows and are very flexible in their alignment during rotation because the center point of the ball in the outer ring is located on the bearing axis. This avoids possible distortions or shaft deflections.

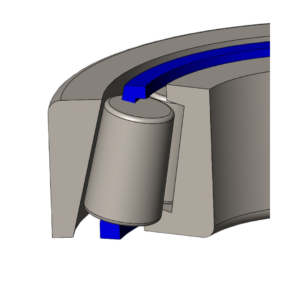

Tapered roller bearings contain conical roller bodies as well as raceways. They can accommodate both radial loads and one-sided axial loads. The inner and outer rings can be mounted independently, as the bearing is not self-retaining. Single-row tapered roller bearings usually require another opposing tapered roller bearing.

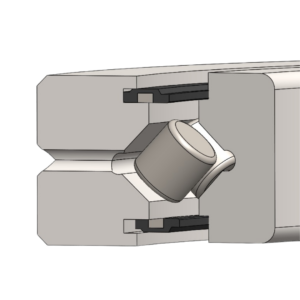

Crossed roller bearings consist of an X arrangement of cylindrical rollers and separating spacers that prevent possible misalignment. The arrangement of the cylindrical rollers allows multiple forces to be accommodated, ensuring a higher rigidity of the bearing. Crossed roller bearings are ideal for use in machine tools, robots, or rotary tables.

Axial roller bearings are capable of withstanding high axial forces. They can be used on one or both sides, but must not be subject to any radial load. The housing washers can be mounted independently of each other and are not self-retaining.

Spindle bearings set the highest demands on speed and accuracy. They enable a reliable operation, which is highly valued in the precision industry. The single-row angular contact ball bearings are self-retaining and available in various tolerance classes.

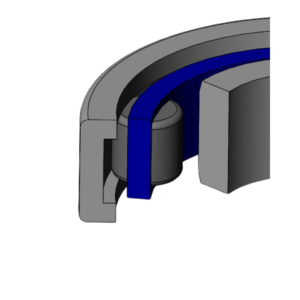

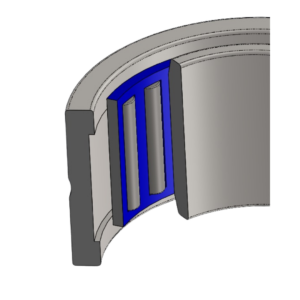

Thin-section bearings are characterized by their special construction.

They consist of a thin outer and inner ring, as well as rolling elements that are housed in a U-shape. An important advantage of thin-section bearings is their compact design, which allows for space savings. They are particularly suitable for applications in confined spaces where high load capacity and a small size are required.

Thin-section bearings are generally able to withstand radial loads and can handle high radial loads. They are also able to handle low axial loads. They are particularly suitable for applications in machine tools, textile machinery, tracked vehicles, and other applications where high load capacity and a compact design are required.

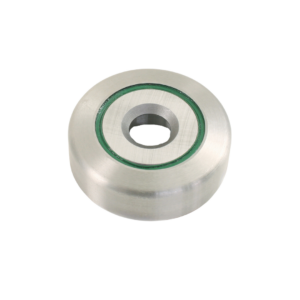

Mast rollers (support rollers) are a special design of ball or cylindrical roller bearings with a solid reinforced outer ring. Unlike rolling bearings, mast rollers are not installed in a housing, but run with their outer ring on a flat or curved running rail. The strength of the outer ring and the roller set is crucial for the load-carrying capacity. A good seal against external contamination and loss of lubricating grease from inside the bearing are of great importance for the service life, in addition to the high load-carrying capacity.

Needle bearings are suitable for applications with limited space and are available in open as well as sealed versions. The cage contains thin needle rollers and is attached to an outer ring or to both an outer and inner ring.

Rolling elements are an important component of every bearing to significantly improve friction and guidance within the bearing. They can usually be divided into balls, cylindrical rollers, and needle rollers. The accuracy of rolling elements is classified in grades. Depending on the application, different materials and sizes are required.

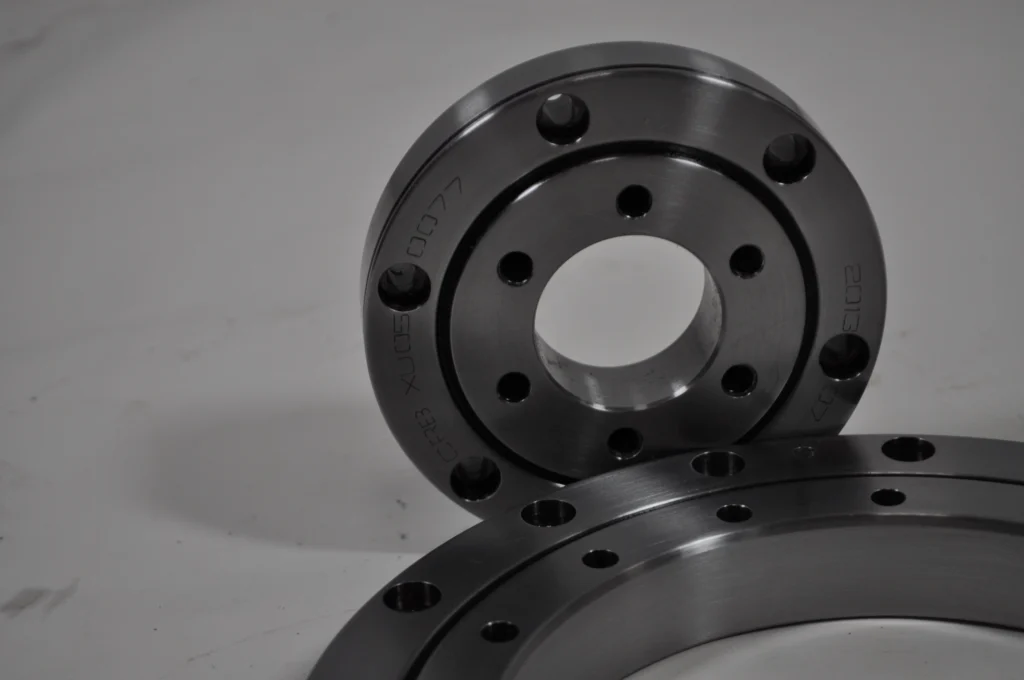

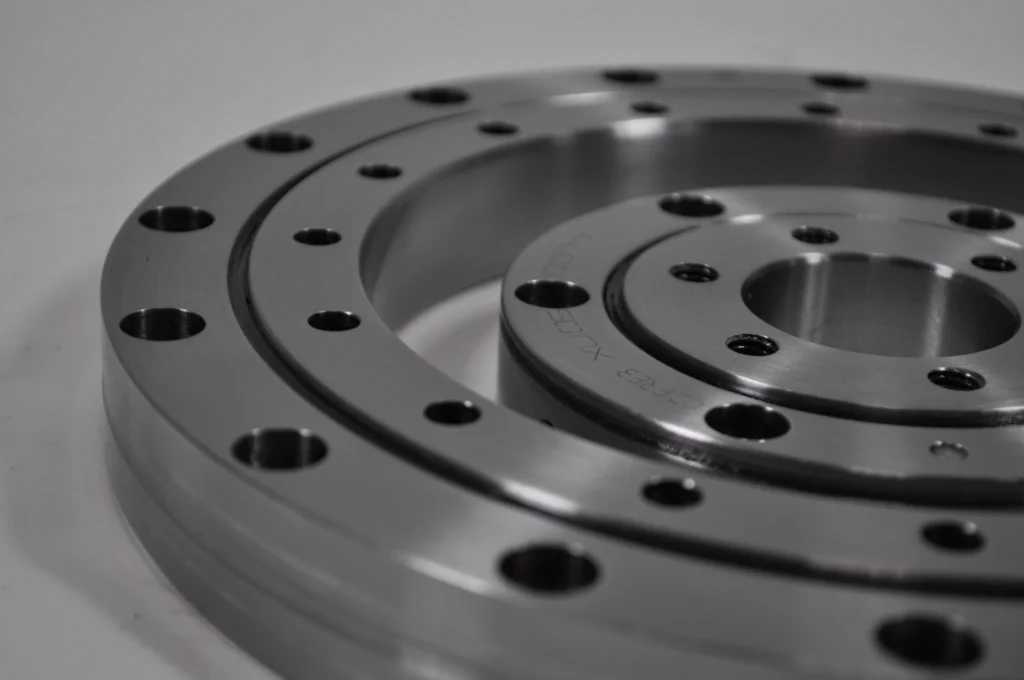

With a machinery park of CNC turning, milling, drilling machines, and 5-axis machining centers, CRB is capable of processing workpieces up to 10 tons and a diameter of up to 2.5 meters in Leverkusen. The ring-shaped parts are the main products of CRB, but cast and forged parts can also be manufactured with the machines according to customer samples or drawings.

Your requirements are welcome, and we are committed to working with you to further develop and grow together.

Consider CRB as your extended purchasing arm to East Asia.

We would be happy to advise you on your project. Please feel free to contact us without any obligation.

©2023 All Rights reserved